“DON’T STRESS, WE’LL TAKE CARE OF THE PROBLEM.”

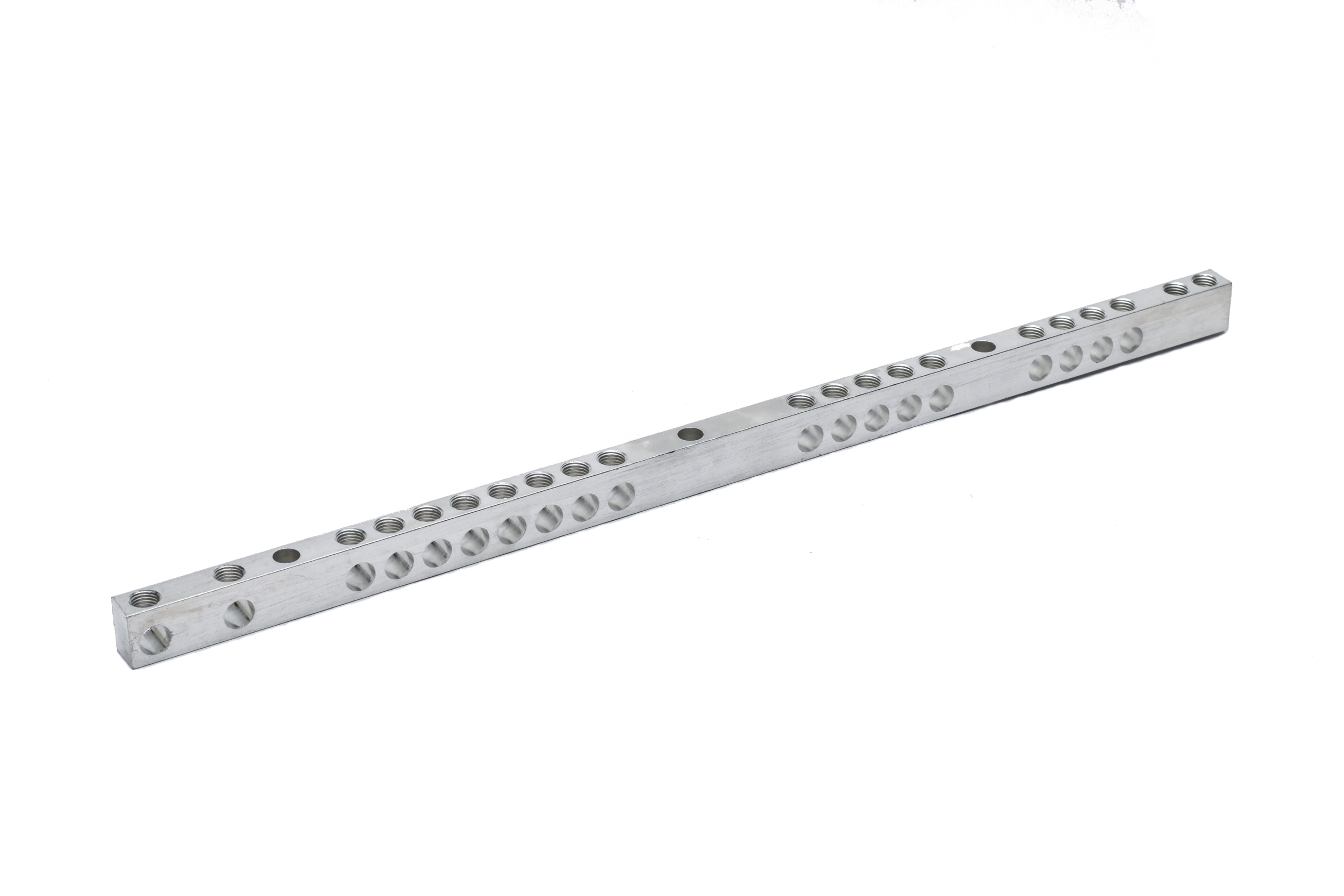

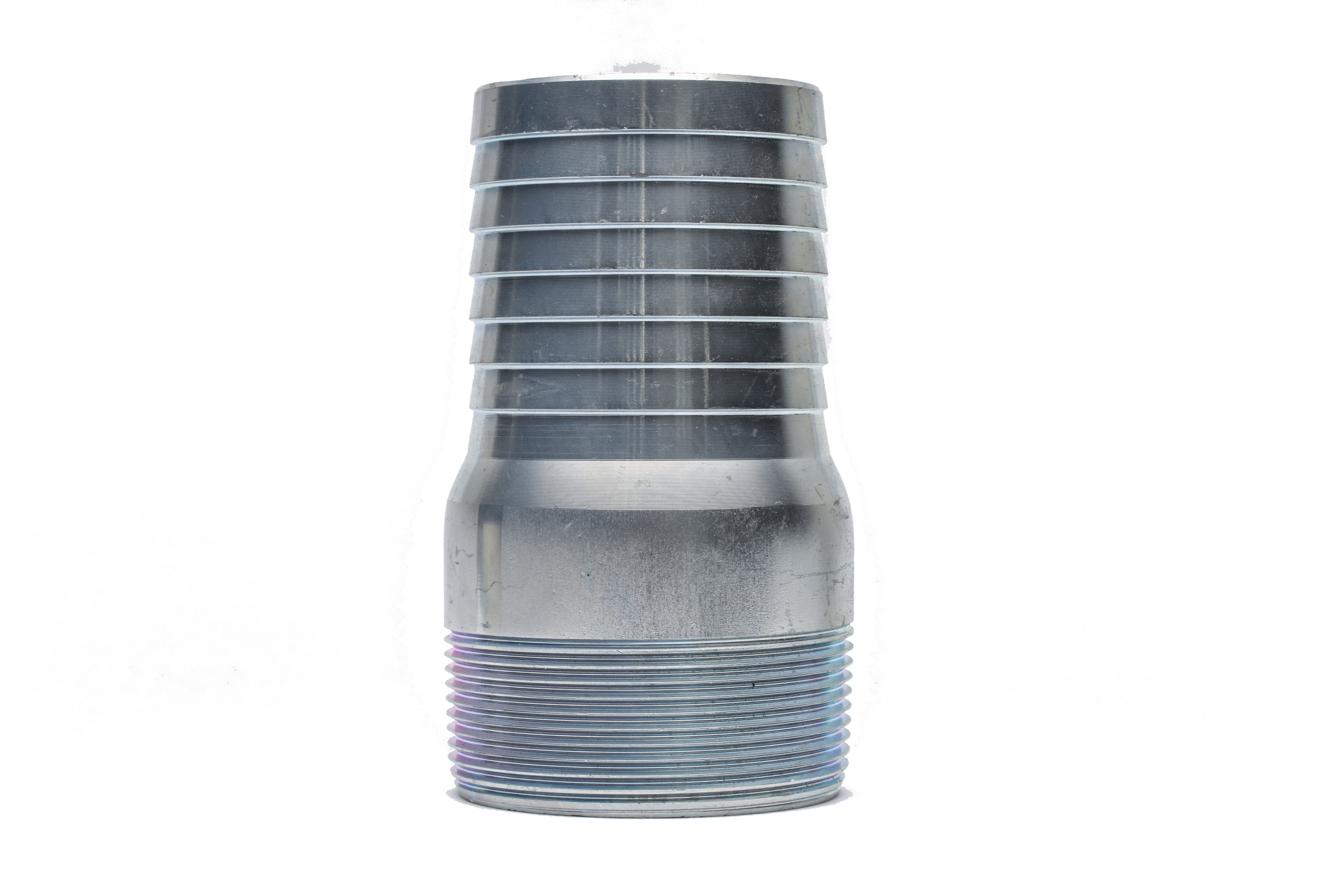

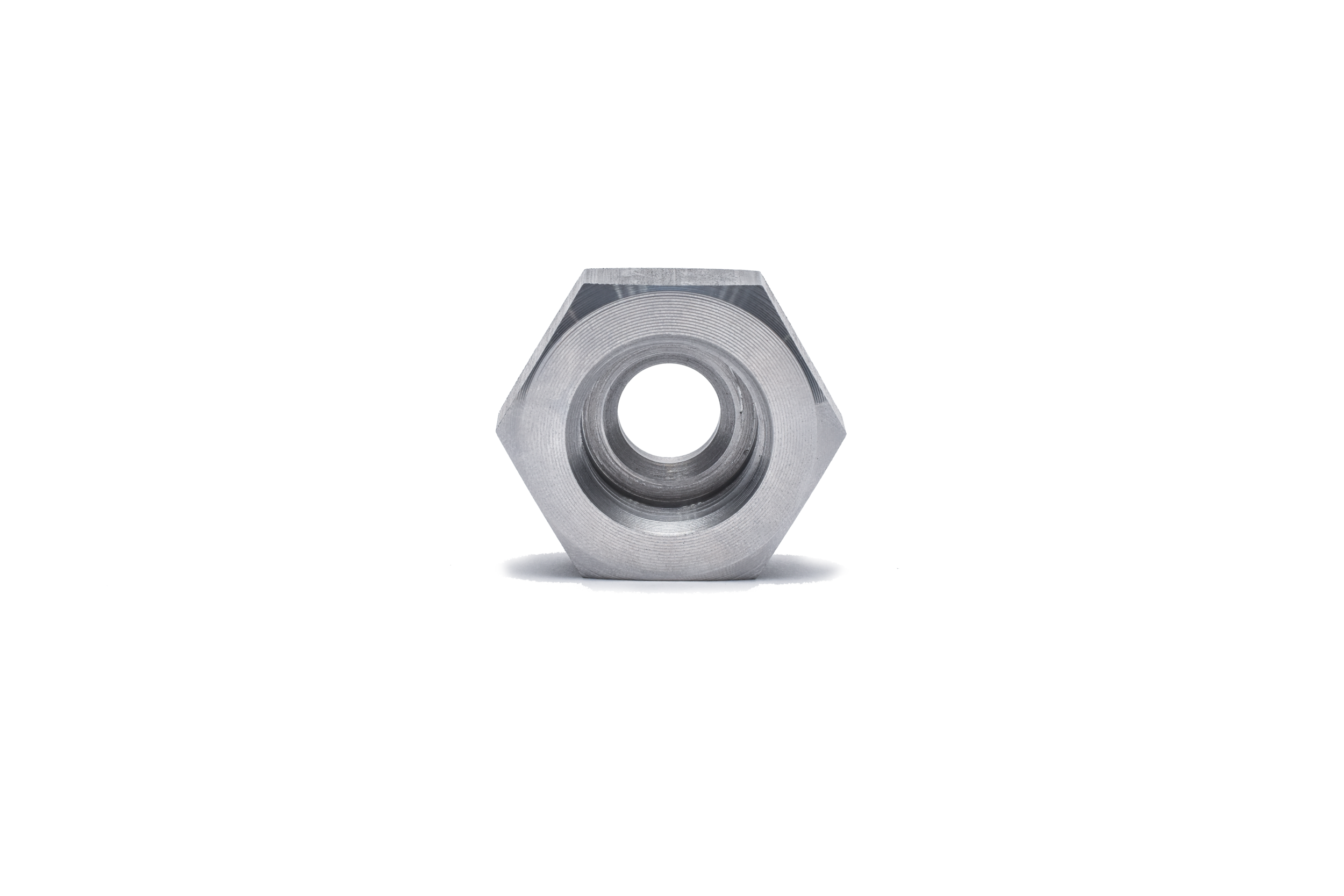

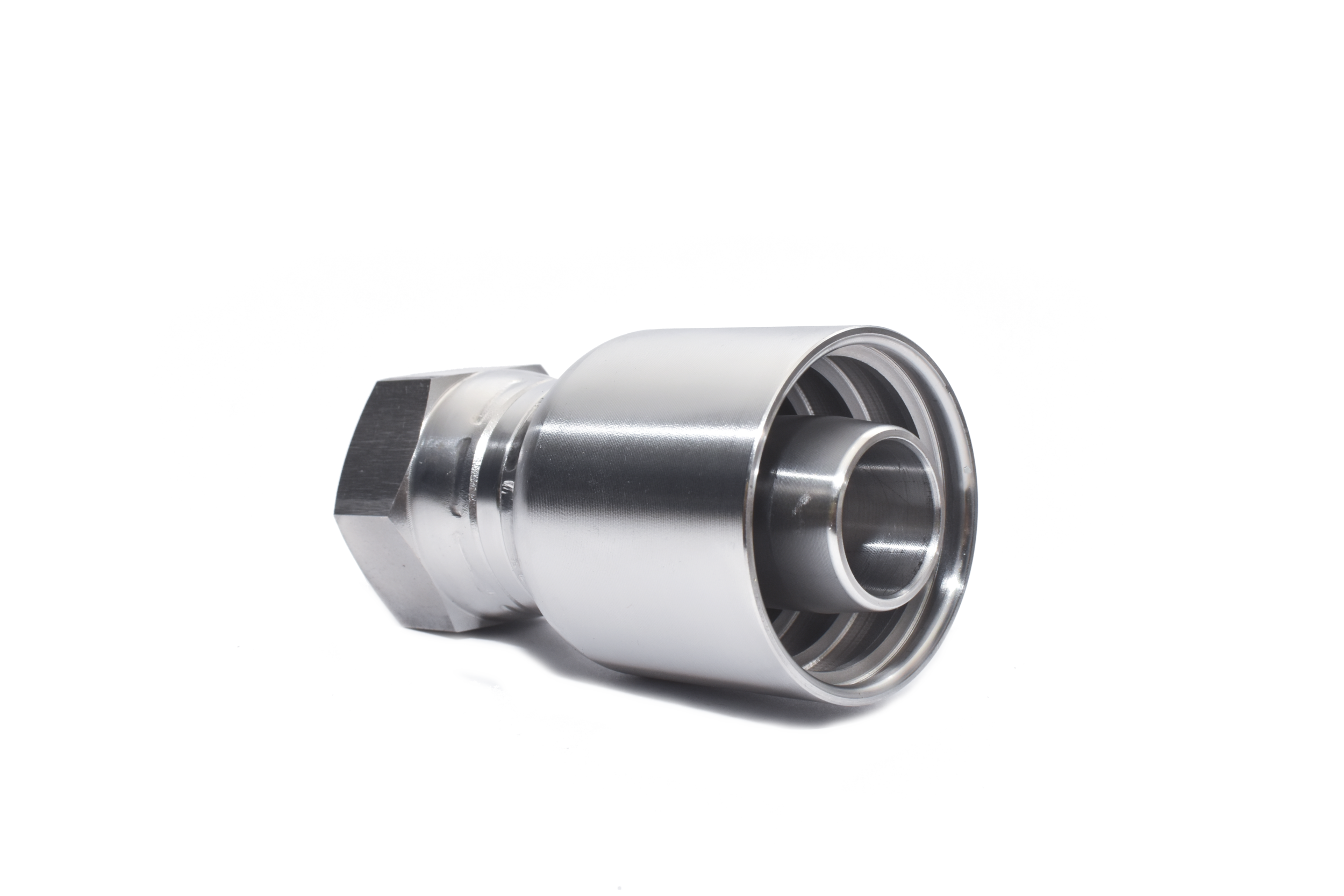

special products

Maybe your machine broke down and you don’t have the spare parts to be able to reactivate your production, or the existing parts are not very resistant which require you to change them continuously or maybe you just want to count with a stock of spare parts to avoid pausing operation as much as possible.

For all of the above, we count with a service for the manufacture of those Special Pieces. This way you won’t have to stop all those processes that matter so much to you.

product engineering

At Tamto we count with an expert department in mechanics, machinery, connections, hydraulics and pneumatics. Capable of analyzing and solving your problem, designing and manufacturing unique parts in rigorous times and with great quality and precision.

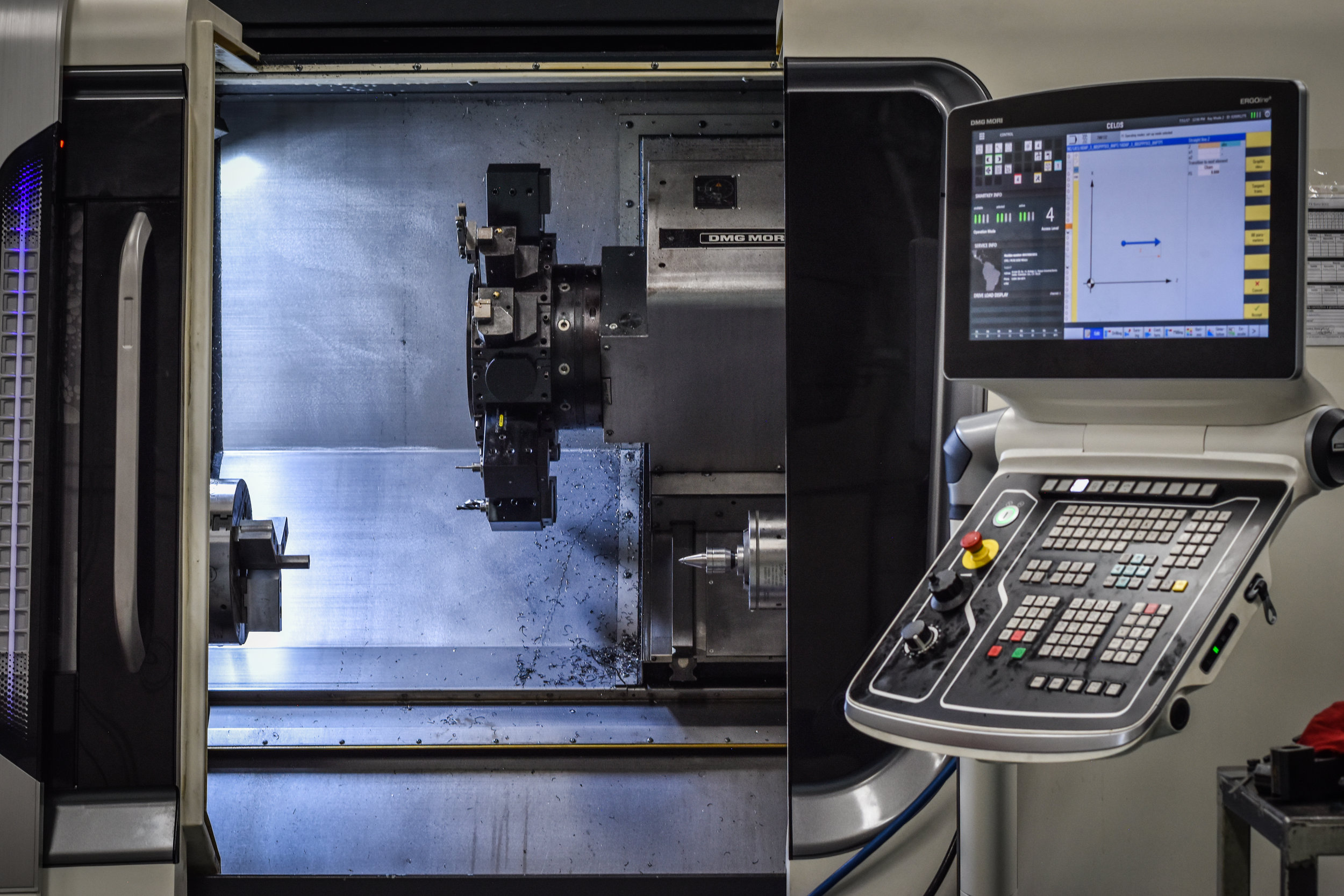

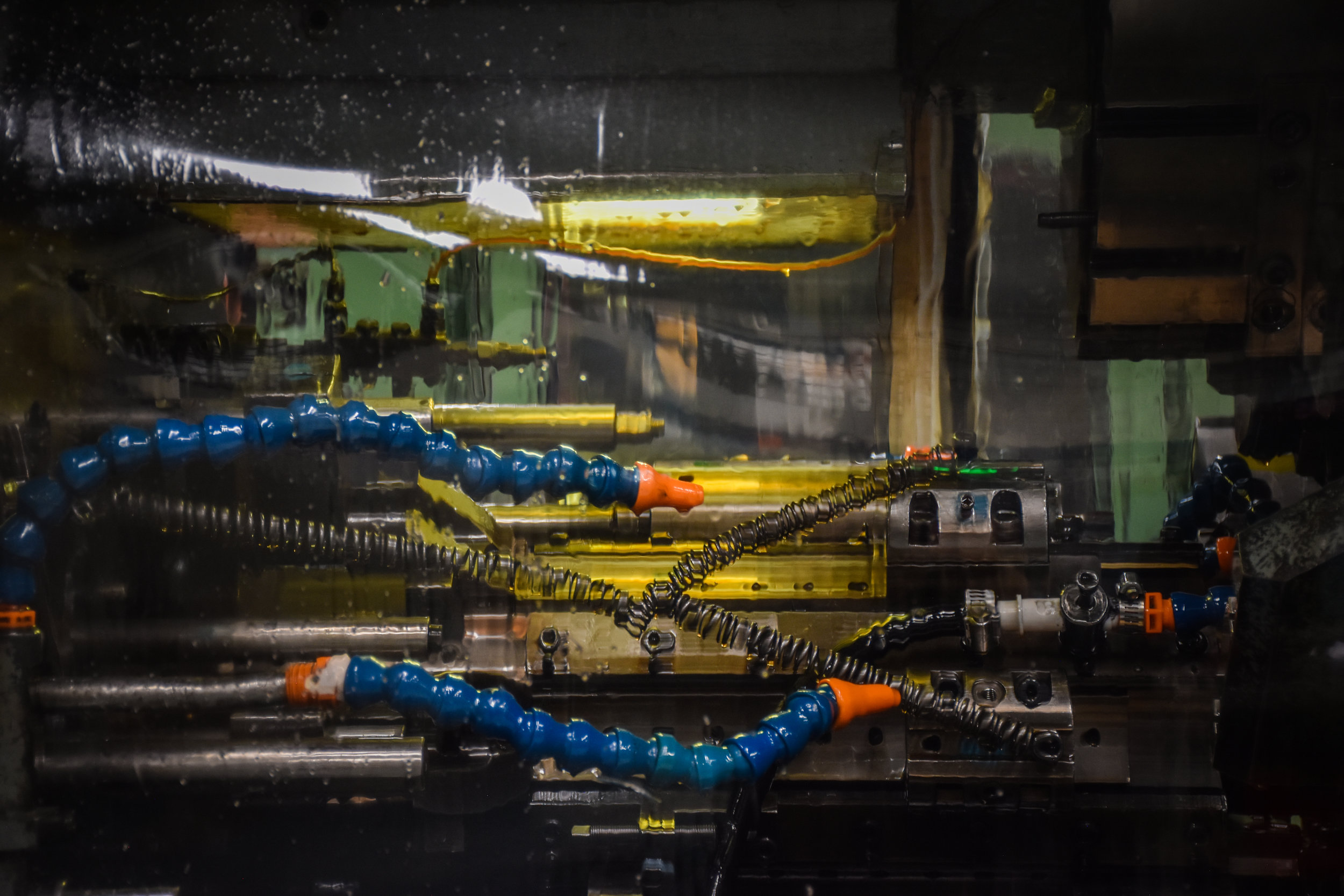

MAchinery

We have a wide range of state-of-the-art machinery and have also developed the experience that allows us to offer a great diversity of processes and strategies to solve the manufacturing of our clients with international standards.

VERTICAL MACHINING CENTERs

7 CNC Machining Centers

Accuracy: ± 0.05 mm

Capacity: X: 700mm Y: 500mm Z: 480mm

CNC LATHES

7 CNC Lathes

Accuracy: ± 0.05 mm

Capacity: Ø From 1.5 mm to 155 mm

DOUBLE SPINDLE CNC MILLING LATHE WITH LIVING TOOLS AND "Y" AXLE

Accuracy: ± 0.003 mm

Capacity: Ø From 1.5 mm to 155 mm

HIGH PRODUCTION LATHES

2 Multi Screw Lathes

8 Automatic Lathes

Accuracy: ± 0.05 mm tolerance

Capacity: Ø From 1.5 mm to 32 mm

RECTIFYING MACHINES

1 Cylindrical grinding machine

Accuracy: ± 0.001 mm

Capacity: Ø From 1.5 mm to 203 mm

Flat grinding machine

Accuracy: ± 0.001 mm tolerance

Capacity: 250 mm x 500 mm x 200 mm

1 Grinding machine without center

Accuracy: ± 0.003 mm

Capacity: Ø from 6mm up to 55mm

HONING MACHINE

Capacity: Ø 1,5 mm up to 165 mm

Length 3 mm up to 400 mm

secondary processes

We make sure that the parts and products that you requested are ready for final use, that’s why we offer you complete solutions and the following secondary processes:

Internal (in house):

Chemical Treatment - Zinc Plated

Chemical Treatment - Nickel Plated

Chemical Treatment - Electro-tinne

Bending of connections in Stainless Steel

Parts cleaning with Sand (Sand Blast)

Parts cleaning - Tamborileado

Mechanical Assemblies

Hydrostatic Testing

External (suppliers):

Annealing

Tempering salt

Vacuum tempering

URGENT ORDERS

We know what it’s like to stop a plant due to a missing piece you can’t find or a spare part that you can’t attain, so in regard we count with a rapid response system where we can give you quotes in a 4-hour response time and quick manufacturing times.

* Ask for our special urgent order service.

* Restrictions apply.

QUALITY SYSTEMS

Our Quality department, made up by a team of 6 highly qualified people that is in charge of quality assurance and the fulfillment of the client's requirements for the products.

We make all of this possible using statistical tools in measurement, data analysis, process control, as well as the implementation and compliance of ISO 9001: 2008 and AS9100C standards.

You can truthfully stay at peace, your production is in professional hands.

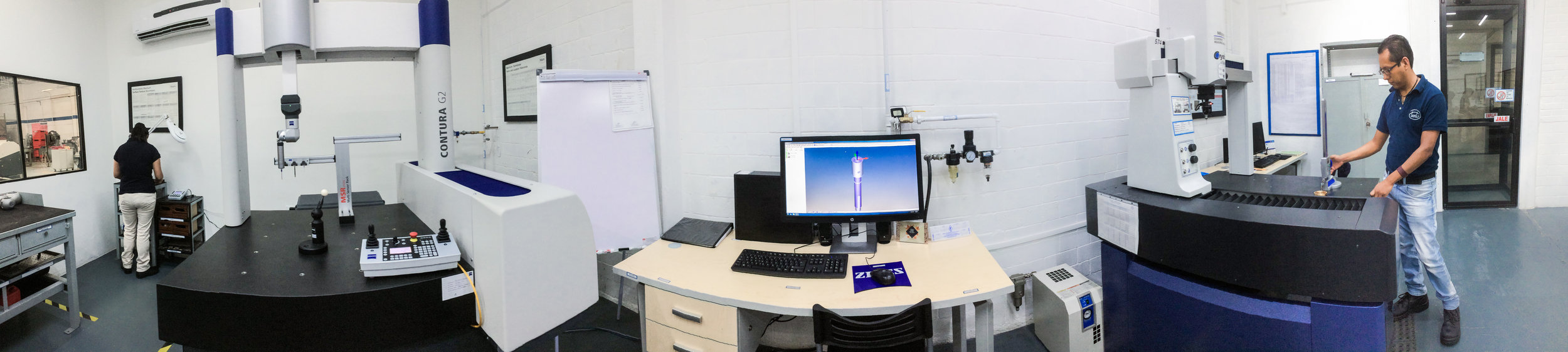

QUALITY LAB

We have a temperature controlled laboratory where we make all of our high precision measurements.

This is where we make sure to verify the effectiveness of our production processes and the repeatability in production so that you always receive the quality you need.

Máquina de Medición por Coordenadas CMM

Mitutoyo

Alcance: 500 mm. en X

700 mm. en Y

400 mm. en z

Precisión: 0.5 micras

Maquina de medición por coordenadas CMM automática Zeiss Contura S2

Rango: 500 mm. in X

700 mm. in Y

400 mm. In Z

DurómetroStarret

Lecturas: Dureza Rwb.

Dureza Rwc.

Rugosímetro Mahr

Lecturas: Rugosidad en Ra.

Rugosidad en Rz.

Bore gage

Torquimetro

Gage Pasa / No pasa

Sala con temperatura controlada 20±1 °C(68 ± 1.8 °F)

ContACT A SELLER

Contact us and in less than 24 hours one of our salesmen will contact you to attend you better.