OUR MISSION IS TO BE YOUR STRATEGIC ALLY IN YOUR SUPPLY CHAIN, OFFERING YOU HIGH-PRECISION MACHINING AND ASSEMBLY SOLUTIONS WITH SECONDARY PROCESSES.

automotive industry

Client: A&P Solutions and Kendrion

Raw material:

12L14 Hexagonal and Round steel.

Heat Treatments:

Zinc plating (Barrel and hung) Zinc-Nickel and Cemented.

Appearance:

Shiny iridescent finish.

Geometric tolerances:

Concentricity, cylindricity, flatness.

Expertise:

Prevent yellowing and presence of rust, knurling configured to customer needs and ensure functionality of coated threads.

Some Applications:

Spray nozzle, Electro fan bulb, Fan shaft, Pipe plugs, Hexagon sockets, Hexagon connectors.

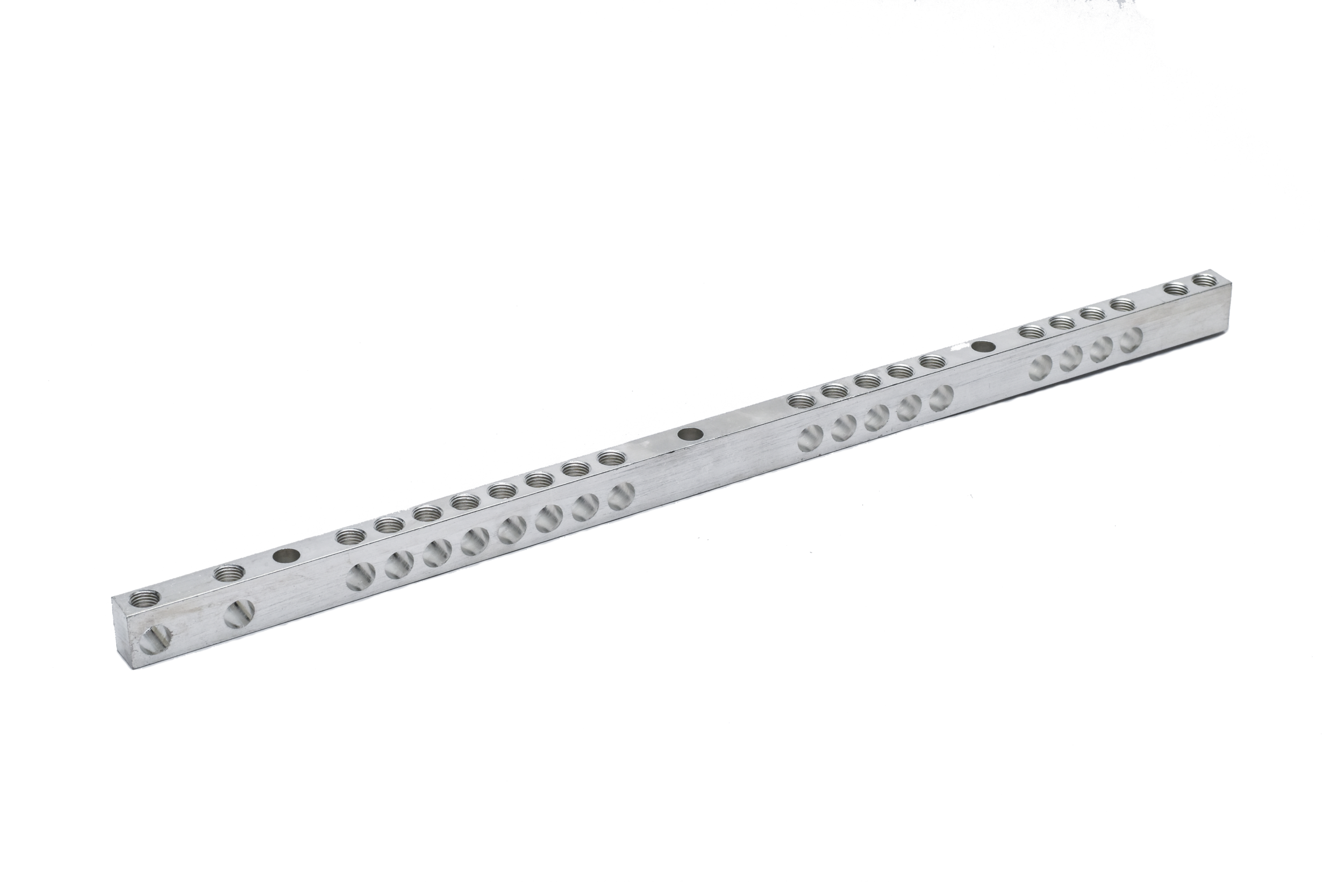

automotive

original equipment

Client: Lunketec and Kb Components.

Raw material:

Carbon and stainless steel.

Aluminum

Heat Treatments:

Zinc plating (Barrel and hung) Zinc-Nickel and Cemented.

Appearance:

Shiny iridescent finish.

Geometric tolerances:

Concentricity, cylindricity, flatness.

Expertise:

Own design with specifications given by the customer.

Some Applications:

Straight, Fork type, Bell, Conical, Drilling, Linear, Revealing between the most important ones.

Rescue industry

Client: Hurst Jaws of Life of IDEX Group.

Raw materials:

Forging 45NICRMO16/X45NiCrMo4.

S7 steel casting.

H13 steel.

Heat Treatments:

Quenching, Tempering, Stress relieving, Phosphating, nitrocarburizing.

Appearance:

Sandblast process with glass bead and roughening.

Geometric tolerances:

Symmetries, concentricity, cylindricity, flatness, perpendicularity.

Experts:

Adjustments and dimensional tolerances in machining processes, as well as in preventing deformations and cracks in these materials.

Some Applications:

High pressure cutters, electric and manual pruning shears, blade replacements.

MAchinery

We have a wide range of state-of-the-art machinery and have also developed the experience that allows us to offer a great diversity of processes and strategies to solve the manufacturing of our clients with international standards.

VERTICAL MACHINING CENTERs

7 CNC Machining Centers

Accuracy: ± 0.05 mm

Capacity: X: 700mm Y: 500mm Z: 480mm

CNC LATHES

7 CNC Lathes

Accuracy: ± 0.05 mm

Capacity: Ø From 1.5 mm to 155 mm

DOUBLE SPINDLE CNC MILLING LATHE WITH LIVING TOOLS AND "Y" AXLE

Accuracy: ± 0.003 mm

Capacity: Ø From 1.5 mm to 155 mm

HIGH PRODUCTION LATHES

2 Multi Screw Lathes

8 Automatic Lathes

Accuracy: ± 0.05 mm tolerance

Capacity: Ø From 1.5 mm to 32 mm

RECTIFYING MACHINES

1 Cylindrical grinding machine

Accuracy: ± 0.001 mm

Capacity: Ø From 1.5 mm to 203 mm

Flat grinding machine

Accuracy: ± 0.001 mm tolerance

Capacity: 250 mm x 500 mm x 200 mm

1 Grinding machine without center

Accuracy: ± 0.003 mm

Capacity: Ø from 6mm up to 55mm

HONING MACHINE

Capacity: Ø 1,5 mm up to 165 mm

Length 3 mm up to 400 mm

SECONDARY PROCESSES

We make sure that the parts and products that you requested are ready for final use, that’s why we offer you complete solutions and the following secondary processes:

Internal (in house):

Chemical Treatment - Zinc Plated

Chemical Treatment - Nickel Plated

Chemical Treatment - Electro-tinne

Bending of connections in Stainless Steel

Parts cleaning with Sand (Sand Blast)

Parts cleaning - Tamborileado

Mechanical Assemblies

Hydrostatic Testing

External (suppliers):

Annealing

Tempering salt

Vacuum tempering

quality system

We have been ISO certified since 2007 and work under the guidelines of the AS9100C aerospace standard. This makes us a company that mitigates risks to their minimum impact and has absolute traceability of its products.

Metrology

We have two CMM machines, a large inventory of testers (Thread, GO/NOGO, attributes, etc.), roughness tester, optical comparator, hardness tester and all the measuring instruments necessary to guarantee, monitor and evaluate each part we manufacture. We seek to exceed your expectations with our expertise.

COORDINATE MEASURING MACHINE

CMM Mitutoyo Manual

Rango: 500 mm en X

700 mm en Y

400 mm en z

Precisión: 0.5 micras

CMM automática Zeiss Contura S2

Rango: 500 mm en X

700 mm en Y

400 mm en Z

measurement tools:

DurómetroStarret

Mediciones de dureza Rwb/Rwc

Rugosímetro Mahr

Mediciones de rugosidad Ra/Rz

Bore gage

Torquimetro

Gage Pasa / No pasa

Sala con temperatura controlada 20±1 °C(68 ± 1.8 °F)

visIT Us

Schedule a visit so you can get to meet our team and our facilities. You will be convinced that your production can’t possibly be in better hands.